Quality

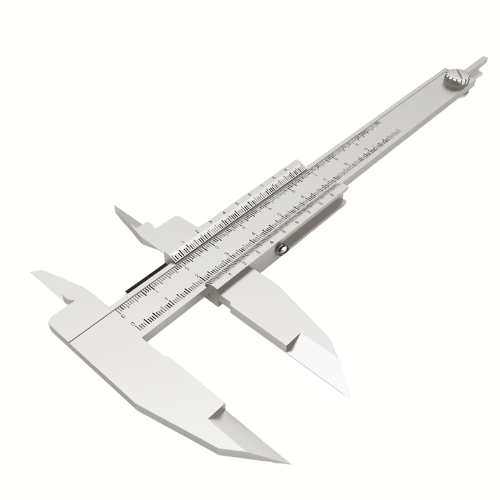

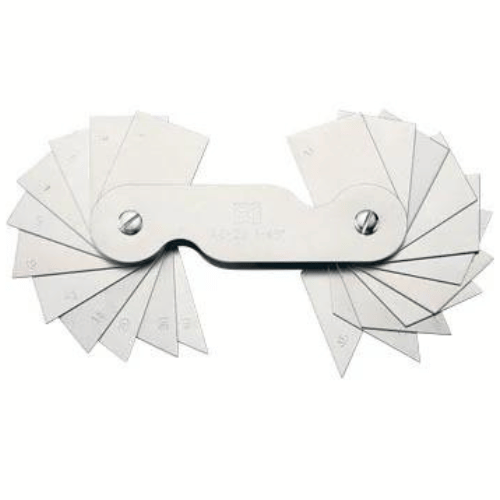

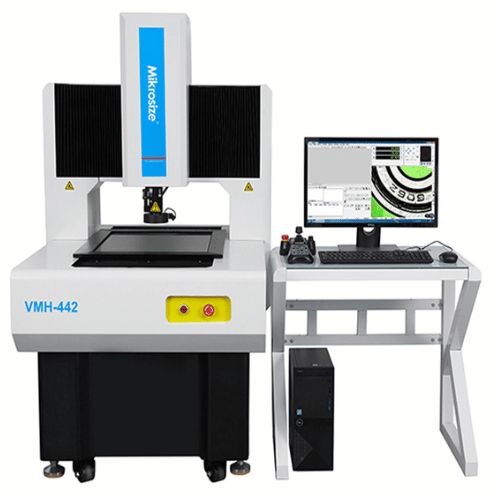

“To uphold our unwavering commitment to quality, we have equipped our facility with a comprehensive array of standardized testing and validation equipment. These essential tools include the rockwell hardness tester for assessing material hardness, height gauges for precise measurements, Vernier calipers for accurate dimensional inspections, micrometers to gauge fine tolerances, surface plates for flatness assessments, and a cutting-edge Vision Measuring Machine (VMM) for intricate and high-precision inspections. Each of these instruments plays a pivotal role in our quality control processes, ensuring that every product we produce adheres to the highest industry standards. Through the rigorous application of these testing methods and technologies, we maintain our reputation for delivering top-notch, reliable components and assemblies to our valued clients.”