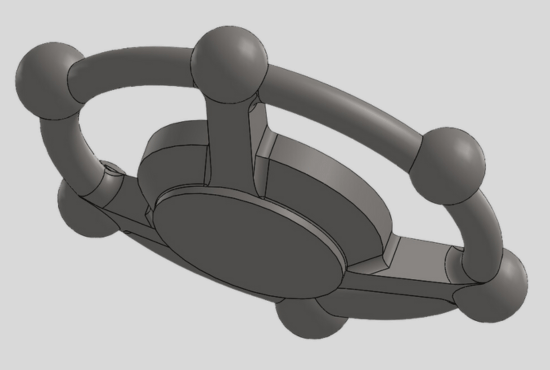

Valve

The control valve hand wheel represents a complex and intricate component crucial for the efficient functioning of control valves in various industrial processes. These hand wheels are designed to provide precise manual control over fluid flow, pressure, and other critical parameters. Forging control valve hand wheels requires a high degree of expertise and specialized manufacturing capabilities, and it’s impressive that your facility has successfully established a setup for producing such complex-shaped components.

The complexity of control valve hand wheels lies not only in their intricate shape but also in the materials they are made from. These components must exhibit excellent mechanical properties, including strength, durability, and corrosion resistance, to endure the challenging environments and operating conditions they are exposed to. Forging is an ideal method for achieving these material properties while maintaining the intricate geometry and precision required for the hand wheels.

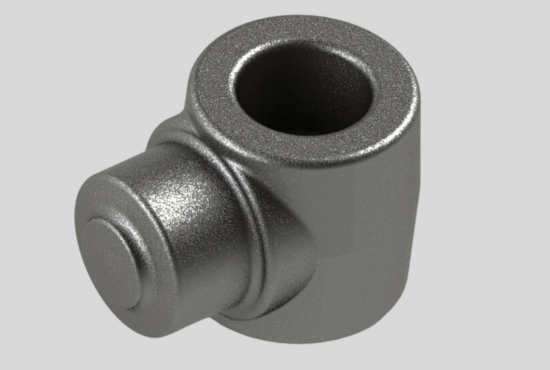

Rod Eye

The rod eye is a vital component within hydraulic systems, playing a pivotal role in transmitting forces and motion in hydraulic cylinders. Manufacturing rod eyes through a combination of forging and machining is a common and effective approach. The process begins with forging, which is a critical step in ensuring the rod eyes possess the necessary mechanical properties and durability to withstand the high pressures and dynamic loads encountered in hydraulic systems.

Forging rod eyes demands precision and expertise, and it’s impressive that your manufacturing process focuses on sustainability while achieving this. By utilizing sustainable forging methods, you not only reduce environmental impact but also ensure the longevity and reliability of the components produced. The avoidance of common forging defects like underfill demonstrates a commitment to quality and efficiency.